The past few days have been quite stressful and at times almost overwhelming. The day after my last post, where I was hoping for no strong winds, we got some terribly powerful winds that tore up some of our Tyvek housewrap and was doing it’s level best to lift the steel roofing panels right off the roof. In the end, everything largely worked out, but it was touch and go there for awhile.

Since then, I have actually gone up on the roof one more time to install the pipe boot around the plumbing vent, so the roof *should* be completely watertight at this point (fingers crossed). It’s quite scary to be up there now as with the cold temperatures, even when the roof is dry, there is very little traction. I *think* (and am choosing to hope) that we got enough done on the roof to get us through until spring.

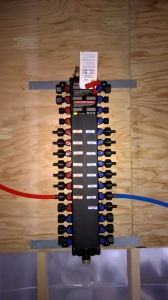

I also ran a few more plumbing supply lines, for the master bath toilet and sink, but it turns out I need to get my hands on some more 90-degree supports for the PEX tubing to run it nicely so they are on order and I am waiting on them to be delivered.

My cousin Jonathan stopped by yesterday after work and the two of us combined managed to wrestle the ridiculously heavy Xantrex off-grid inverter up onto the wall. So now I have all the main boxes (inverter, distribution cabinet, and both solar charge controllers), except the main A/C supply box, mounted up on the wall and ready to be wired.

You can also see our Venmar HRV in the foreground of that picture, it’s almost ready to get hung up from the joists and have the ducting run.

Finally, in amongst all that, I’ve been working on our electrical plan and getting my shopping list together to get that underway, and managed to finish putting up the housewrap on the last end of the house:

Tomorrow Jonathan will be returning with his truck, and we’ll drive over to Smiths Falls and pick up our two hot water heaters, and get them located in the basement, in preparation to connect them to the propane system. Hopefully that goes smoothly.

Take care and thanks for reading!